350mm

330mm

600mm

650mm

80kg

510*(25~100)*203.2/ optional 510*(25~100)*203.2

7.5 (Optional 11) Kw

60m/s (Optional 100m/s)

67 mm

Bearing type spindle(high-speed electric spindle optional)

Dead center/ Movable center

MT5

10~1000rpm

2 Kw

MT4

58mm

35mm

400mm

16M/min

0.001/0.01/0.10mm

Plunge/Angular

2.2 Kw

A-V-flat structure guide rail

700mm

16 M/min

0.001/0.01/0.10mm

2.2 Kw

A-V flat structure guide rail

4 degrees of clockwise rotation/9 degrees of counterclockwise rotation

1/4HP

1/4HP

25w/HP

30L

120L

8L (with full-time lubrication)

5200kg

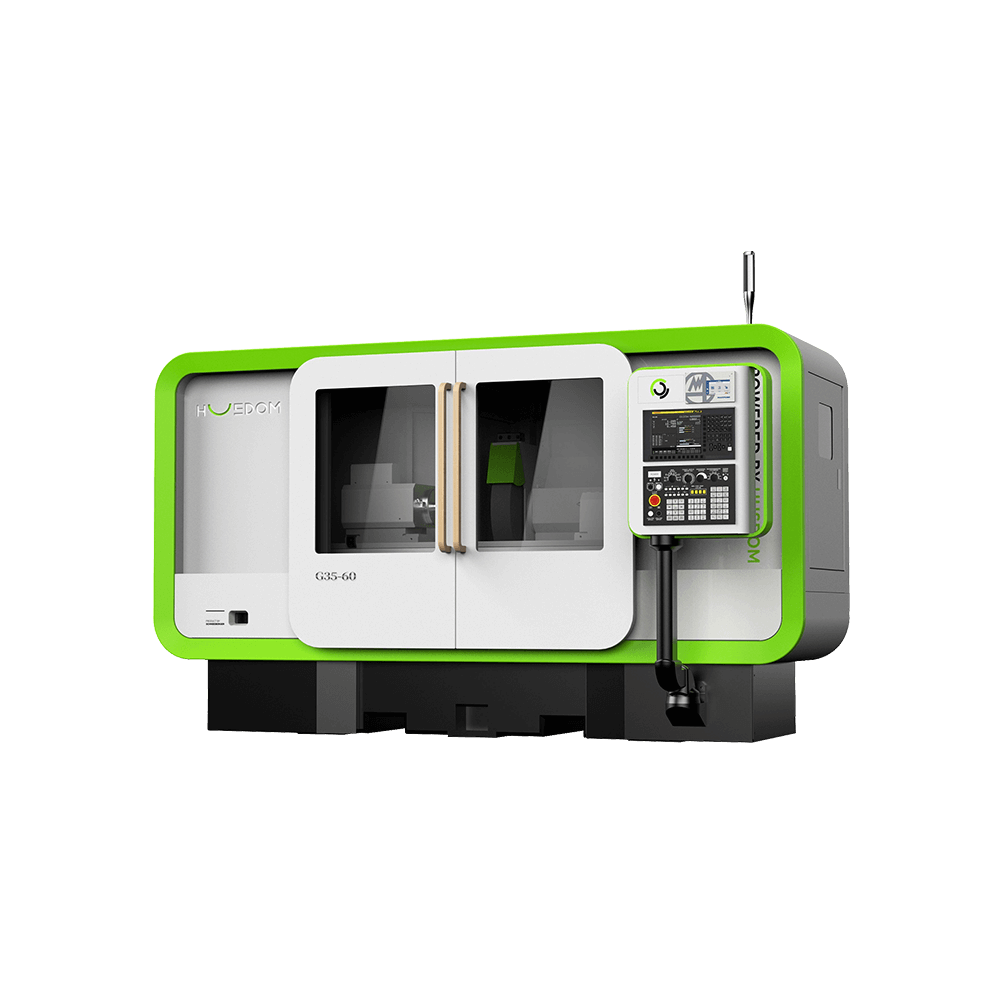

3200L*2500W*1900H mm

| SCHNEEBERGER mineral casting

| FANUC CNC Controller System

| Standard Water Tank: 120L/min capacity, 140L (including paper tape magnetic filter)

| Lead Screw(THK C1 Grade)

| Bellows Cover (THODACON)

| Constant Linear Speed for Wheel Spindle

| Trigonal Dresser x1 / Diamond Dresser x3

| Workpiece Spindle (MT5) / Stepless Variable Speed Servo Motor

| Full Enclosure Sheet Metal

| Face Measurement Device (MARPOSS)

| Basic Installation Accessories

| Internal Work Area LED Lighting

| Fan-Type Oil Temperature Cooler

| Operation Manual and Parts List

| Tungsten Steel Center (MT4/MT5)

| Standard Grinding Wheel + Wheel Flange

| Adjustment Tools and Toolbox

| Circuit Diagram

| Electrical Cabinet Heat Exchanger

| MPG Electronic Handwheel 2-Axis Control

| Wheel Dismounting Tool

l Roller grinding base

l Forming roller

l Cutting oil constant temperature air conditioner

l Optical scale (Fagor, HEIDENHAIN)

l Oil mist recovery machine